Fiber Optic Logging And Monitoring

Voltage Wireline is working in partnership to bring advanced fiber optic sensing technology to the Oil & Gas industry. Voltage has a strong technical sales and service team dedicated to the deployment and advancement of this technology, both in field applications as well as data processing and interpretation. Ever-expanding technologies are closely followed to best maximize our use of the newest and best products available.

- Fiber Optic Distributed Temperature Survey: “DTS”

- HiFi MiQro Fiber Optic Noise Logging

Surface Casing Vent Flow / Gas Migration Solutions

Voltage Wireline has helped develop and tailor custom logging suites to help solve the ongoing issues of Surface Casing Vent Flow (SCVF) & Gas Migration (GM). Working with industry leaders in Fiber Optic and formation evaluation technology, Voltage’s dedicated team of Log Analyst’s and technical staff have proven to be accurate and efficient in SCVF & GM source identification. These services can be conveyed in real-time with E-line or E-coil.

- Fiber Optic Directional Noise Tool: “MiQro”

- Traditional Noise Tool: “NT”

- Temperature Log: “TP”

- Fiber Optic Distributed Temperature Survey: “DTS”

- Cased Hole Analysis Tool: “CHAT”

- Radial Bond Log: “RBL”

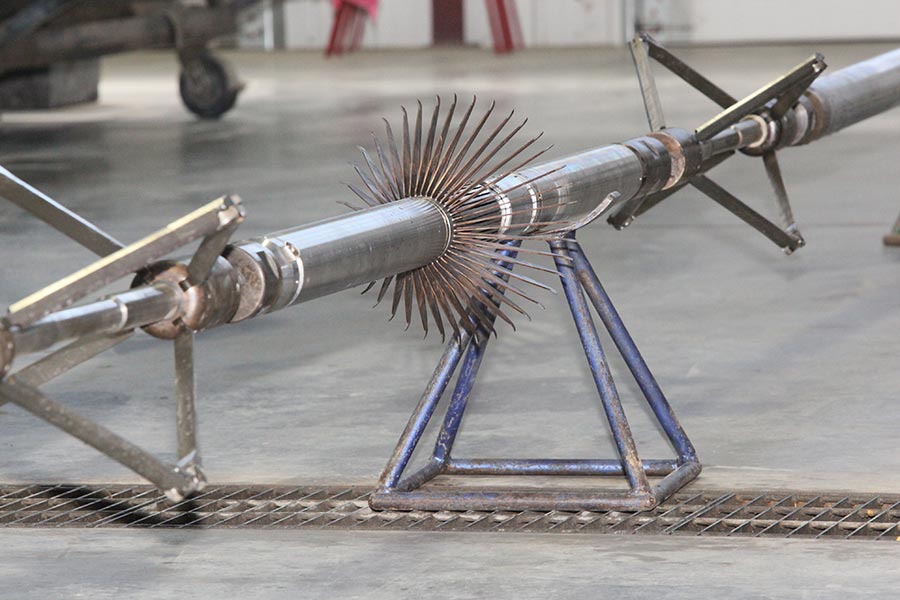

Casing Integrity Solutions

Voltage Wireline uses the Sondex Multi-Finger Imaging Tool (MIT) in combination with the Magnetic Thickness Tool (MTT) to inspect casing or tubing defects including metal loss, drilling wear, corrosion, deformations, cracks, holes and scale build up. These tools have a proven track record for accuracy and reliability and are accepted by the AER as a compliant alternative to directive 51 and Directive 36. This service can be conveyed in real time with E-line, E-coil or in memory mode with standard coil tubing or slickline.

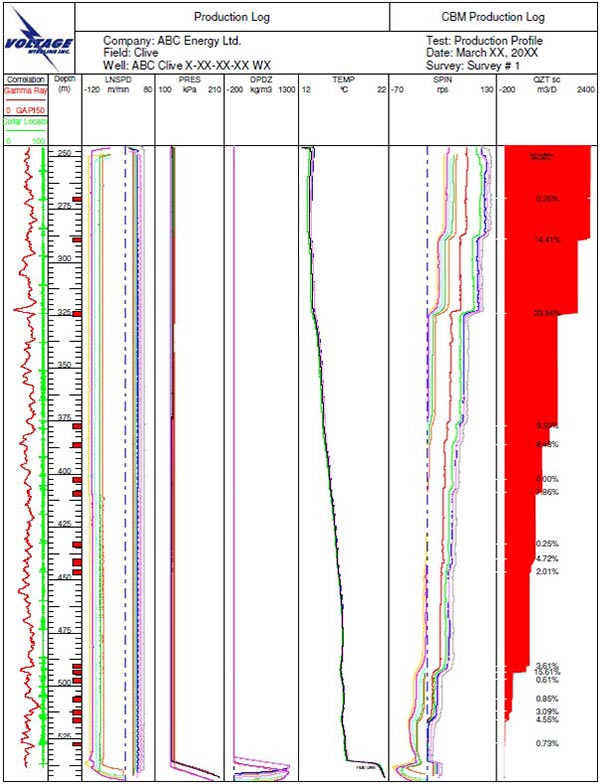

Production Logging

Whether it be production or injection profiling, Voltage Wireline has a wide range of production logging tools that are used for vertical, and deviated wells. Our Production Logging tools are completely combinable and provide accurate measurements of flow velocity, gas hold up, fluid velocity, fluid density and other auxiliary measurements. These services can be conveyed in real time with E-line, E-coil or in memory mode with standard coil tubing or slickline.